Inducing Head

Inducing Head Specification

- Shape

- Cylindrical

- Features

- High Durability, Enhanced Precision, Easy Installation

- Surface Finish

- Smooth Finish

- Capacity

- Light & Medium Load

- Noise Level

- <70 dB

- Lubricating System

- Automatic Lubrication

- Motor Power

- 0.75 kW

- Diameter

- 75 mm

- Size

- Standard

- Usage & Applications

- Industrial Applications, Mechanical Assemblies

- Drive Type

- Direct Drive

- Product Type

- Inducing Head

- Material

- High-Grade Steel

- Technology

- Precision Machining

- Power Source

- Electric

- Power

- 0.75 kW

- Voltage

- 220-240 V

- Pressure

- Up to 5 Bar

- Surface Treatment

- Corrosion Resistant Coating

- Dimension (L*W*H)

- 230 x 150 x 120 mm

- Weight

- 4.5 kg

- Color

- Metallic Grey

- Connection Type

- Bolt-On

- Mounting Type

- Flanged Mount

- Packaging

- Export Quality Box

- Frequency

- 50 Hz

- Operational Speed

- Up to 1500 rpm

- Temperature Range

- -10°C to 80°C

- Maintenance

- Low Maintenance

- Compatibility

- Standard Coupling Systems

- Seal Type

- Double-sealed

About Inducing Head

An Inducing Head, also known as an induction coil or inductor, is an electrical device used in induction heating systems. It consists of a coil made of copper or other conductive material that generates a magnetic field when an alternating current passes through it. The Inducing Head is placed near or around the object to be heated, allowing the magnetic field to induce electrical currents in the object, resulting in rapid and controlled heating. Inducing Heads find applications in various industries, including metalworking, automotive, and manufacturing processes that require precise and efficient heating.

FAQs (Frequently Asked Questions) :

Q: What is an Inducing Head?

A: An Inducing Head is an electrical device used in induction heating systems. It consists of a coil made of conductive material, typically copper, which generates a magnetic field when an alternating current passes through it. The magnetic field induces electrical currents in nearby conductive objects, leading to efficient and controlled heating.

Q: How does an Inducing Head work?

A: An Inducing Head works based on the principle of electromagnetic induction. When an alternating current flows through the coil of the Inducing Head, it creates a changing magnetic field around the coil. This magnetic field then induces eddy currents in conductive objects placed near the coil, resulting in the generation of heat.

Q: What are the advantages of using an Inducing Head for heating?

A: Inducing Heads offer several advantages for heating applications. They provide rapid and localized heating, allowing for precise control over the heating process. Induction heating is energy-efficient, as it directly heats the object without the need for a heat transfer medium. Additionally, induction heating offers uniform heating, reduces cycle times, and enables selective heating of specific areas, making it suitable for various industrial applications.

Q: What materials can be heated using an Inducing Head?

A: Inducing Heads can heat a wide range of conductive materials, including metals such as steel, aluminum, copper, brass, and various alloys. The ability to heat different materials depends on their electrical conductivity and magnetic permeability. Non-conductive materials, such as plastics or ceramics, do not typically respond to induction heating.

Durability and Precision Engineering

Our Inducing Head is crafted from premium-grade steel using advanced precision machining techniques, ensuring high durability and superior operational accuracy. With a corrosion resistant finish and double-sealed design, it is built to withstand harsh industrial environments while maintaining peak performance.

Effortless Installation and Compatibility

This unit incorporates a flanged mount and bolt-on connection, simplifying the installation process and minimizing downtime. Its standardized dimensions and compatibility with standard coupling systems make it a seamless fit for a variety of mechanical assemblies and industrial setups.

Enhanced Performance and Low Maintenance

With an automatic lubrication system, the Inducing Head requires minimal upkeep, reducing maintenance costs and interruptions. Operating smoothly at speeds up to 1500 rpm with noise levels under 70 dB, it provides reliable, efficient performance, even under demanding conditions.

FAQs of Inducing Head:

Q: How is the Inducing Head installed in industrial applications?

A: The Inducing Head uses a flanged mount and bolt-on connection, making installation straightforward. Simply align the flange with the mounting surface and secure it using bolts, ensuring compatibility with standard coupling systems.Q: What benefits does the double-sealed design provide?

A: The double-sealed mechanism ensures superior protection against dust, moisture, and contaminants, thereby extending equipment lifespan, enhancing reliability, and reducing maintenance requirements.Q: What types of machinery or systems are suitable for this Inducing Head?

A: It is ideally suited for various industrial applications, including mechanical assemblies using standard coupling systems, light and medium load operations, and environments requiring high durability and precision.Q: When is maintenance required for the Inducing Head?

A: Thanks to its automatic lubrication system and robust, low-maintenance design, regular manual maintenance is seldom needed. Scheduled inspections consistent with industry best practices are recommended.Q: Where does this product stand out compared to alternatives?

A: This Inducing Head offers enhanced precision, easy installation, and dependable performance with corrosion-resistant, export-quality packagingmaking it a preferred choice for dealers, exporters, and suppliers across India.Q: What process is involved in ensuring export quality packaging?

A: Each unit is packaged in a sturdy, export-quality box to protect the product from damage during transit, guaranteeing it arrives in optimal condition for distributors, dealers, and wholesalers.Q: What are the key operational parameters for safe and efficient performance?

A: The Inducing Head is engineered for use at up to 1500 rpm, within temperatures of -10C to 80C, and at pressures up to 5 Bar. It operates on 220-240 V electric power at 50 Hz and supports a direct drive system, maintaining noise levels below 70 dB.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Milling Accessories Category

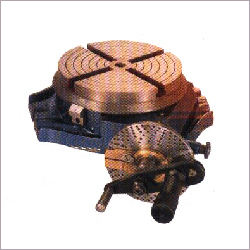

Rotary Table

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Galvanized

Color : Golden

Product Type : Machine Accessories

Technology : CNC

Digital Readouts

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Coated

Color : Black and White

Product Type : Machine Accessories

Horizontal Milling Attachment

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Painted

Color : Blue and Black

Product Type : Machine Accessories

Indexing Milling Attachment

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Painted

Color : Red

Product Type : Machine Accessories

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS