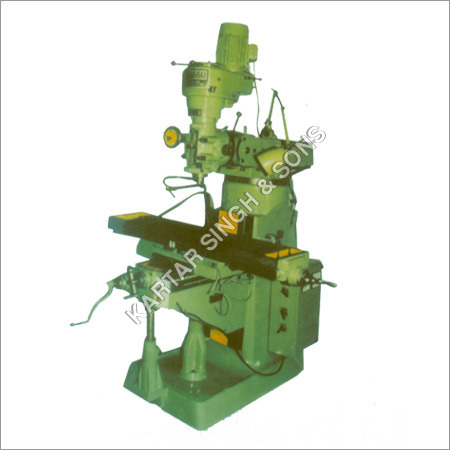

Mini Horizontal Production Milling

Mini Horizontal Production Milling Specification

- Product Type

- automatic milling machine

- General Use

- Industrial

- Material

- Cast Iron

- Computerized

- No

- Automatic

- Yes

- CNC Or Not

- Normal

- Feature

- High Performance

About Mini Horizontal Production Milling

A Mini Horizontal Production Milling machine is a compact and versatile milling tool used for precision machining in small-scale production environments. It is designed to perform horizontal milling operations, where the cutting tool rotates parallel to the workpiece. Despite its small size, the Mini Horizontal Production Milling machine offers high accuracy and efficiency, making it suitable for tasks such as slotting, grooving, and contouring of various materials.

FAQs :

Q: What is a Mini Horizontal Production Milling machine?

A: A Mini Horizontal Production Milling machine is a compact milling tool used for precision machining in small-scale production settings. It is designed to perform horizontal milling operations, where the cutting tool rotates parallel to the workpiece. The machine is typically smaller in size compared to larger industrial milling machines but offers high accuracy and efficiency.

Q: What are the advantages of using a Mini Horizontal Production Milling machine?

A: Mini Horizontal Production Milling machines offer several advantages. They are compact, making them suitable for limited workspace or small-scale production environments. These machines provide high precision and versatility for various milling operations, allowing for the creation of intricate parts with tight tolerances. Mini Horizontal Production Milling machines are also known for their ease of use and cost-effectiveness.

Q: What materials can be machined using a Mini Horizontal Production Milling machine?

A: Mini Horizontal Production Milling machines can work with a wide range of materials, including metals like steel, aluminum, brass, and copper. They are also capable of machining certain plastics and composites. The choice of cutting tools and machining parameters depends on the specific material being machined.

Q: What are some common applications of Mini Horizontal Production Milling machines?

A: Mini Horizontal Production Milling machines find applications in various industries and workshops. They are commonly used for tasks such as slotting, grooving, contouring, and drilling. These machines are especially useful for small-scale production runs, prototyping, and repair work.

Q: Are Mini Horizontal Production Milling machines suitable for beginners?

A: Mini Horizontal Production Milling machines may require some level of experience or training to operate effectively. While they can be used by beginners, it is recommended to receive proper training in milling operations and safety procedures before operating the machine independently.

Q: Can Mini Horizontal Production Milling machines be automated or computer-controlled?

A: Yes, some Mini Horizontal Production Milling machines can be equipped with automation features or retrofitted with computer numerical control (CNC) systems. This allows for automated machining operations and programmable control, enhancing precision and productivity.

Q: What are the size and capacity limitations of Mini Horizontal Production Milling machines?

A: The size and capacity of Mini Horizontal Production Milling machines can vary depending on the specific model. As they are designed for small-scale production, they generally have a smaller work envelope and limited cutting capacities compared to larger industrial milling machines. It is important to review the specifications of each machine to ensure it meets the required size and capacity requirements for the intended applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Milling Machines Category

Turret Milling Machine

Minimum Order Quantity : 1 Unit

Automatic : Yes

CNC Or Not : Normal

Material : Galvanized Steel

Computerized : Yes

Control System : Manual

Precision Turret Milling Machine

Minimum Order Quantity : 1 Unit

Automatic : Yes

CNC Or Not : Normal

Material : Galvanized Steel

Control System : Manual

Milling Machine

Minimum Order Quantity : 1 Unit

Automatic : No

CNC Or Not : Normal

Material : Galvanized Steel

Computerized : Yes

Control System : Manual

Milling Machine VEH3

Automatic : No

CNC Or Not : Other, Not CNC

Material : Other, Metal

Computerized : No

Control System : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS